Actions on recycling

- Commitment #7 -

Focus 2023

Massifying collection, the challenge of reuse

At a time when reuse is taking root in people's minds and practices across Europe, CEPOVETT is pulling out all the stops to increase its collection of end-of-life garments from its customers. Appropriate logistics and the massification of flows are essential if a second-hand sector is to be established. In 2023, the company aims to increase the collection rate among its customers and increase its stock of clothes dedicated to reuse, notably through incentive systems for wearers and specific communication on the meaning given to the recycling action. Committed since 2014 to an ambitious approach to recycling professional clothing with its customers, the company has for several years been deploying an effective, easy-to-use collection tool, the BoxTextile, which enables post-consumer used clothing to be collected from customers.

Focus 2022

Recycled tote bag made of patchwork fabric

Upcycling is being experimented in our Madagascan production workshop EPSILON/ CEPOVETT as one of the possible ways to recycle our customers' fabric scraps.

This virtuous solution consists in reusing fabric scraps from the manufacture of the workwear it produces, to make patchwork tote bags. A way of recycling waste, this innovative process enables textiles to be used in their entirety and transformed into accessories. The fabrics used for the tote bags were collected from all the company's customers, becoming a showcase for our customers' fabrics. Each bag contains around 80 pieces assembled using the traditional Anglo-Saxon sewing technique, which involves sewing small pieces of different fabrics together to create a colorful, aesthetically pleasing whole. This initiative has a dual ecological and educational vocation. The "made in Madagascar" tote bags enable trainee seamstresses to practice on the factory's production line.

Focus 2021

CETI: a research center serving the textile industry

The CETI, European Center for Innovative Textiles, is a research and innovation center, supported by the Up-Tex competitiveness cluster, which aims to boost the textile industry.

Created in 2012 thanks to the mobilization of players in the fi lior and fi nancial support from the French State, Lille Métropole Communauté Urbaine, the Nord Pas-de-Calais Region, Europe and the Département du Nord, CETI serves companies to encourage and accelerate innovation. It is a place to design, experiment, prototype and industrialize new products, materials and processes adapted to the needs of industry. It collaborates with producers, major brands and distributors in the fashion, sports, luxury and technical textiles sectors. Its international dimension places it among the Top 5 technical centers worldwide. As part of its co-creation strategy, CETI integrates the digital dimension, making textiles a vector for innovation.

Focus 2020

Corporate upcycling, a way of the future

Corporate upcycling is an innovative and symbolic approach to the circular economy, based on recycling, social integration and solidarity-based reuse, which enables companies to illustrate their waste strategy, while meeting their CSR challenges. The aim is to transform used clothing into meaningful, desirable business accessories. More and more companies are launching projects in this direction, with the aim of upgrading their employees' uniforms or professional textiles by transforming them into useful objects. This approach is often coupled with collaboration with adapted workshops, in partnership with players working towards social reintegration and inclusion. Corporate upcycling not only gives a second life to work clothes, but also a second chance to employees on the road to professional and social integration.

Focus 2019

Praxy recovers non-recyclable CEPOVETT Group textiles

The French Energy Transition Law for Green Growth has set the target of reducing the tonnage of waste sent to landfill by 50%. But some waste cannot be recycled. The geographical proximity of the Bourgogne Recyclage processing center (Praxy network) reduces the carbon impact of CEPOVETT Group's transport flows to less than 50 km, and offers ultra-modern facilities for the manufacture of solid recovered fuels (SRF). CEPOVETT Group is committed, alongside Bourgogne Recyclage, to a "made in France" CSR process for recycling its most demanding and complex textile wastes, capitalizing on the advantage of double recovery, in terms of energy substitution and ash reclamation.

Focus 2018

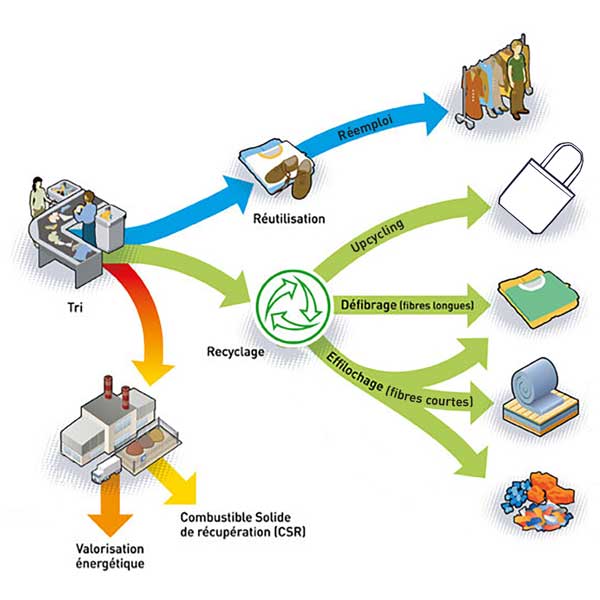

A second life for our professional clothing

CEPOVETT Group has made the recycling and end-of-life of its products a priority in its corporate social responsibility policy, in association with exclusive leading industrial partners, to invent innovative, tailor-made solutions that are both socio-economic and environmental. Since 2011, CEPOVETT Group's recycling program has been using a variety of methods to recycle end-of-life professional textiles: sound and heat insulation for the automotive and housing industries, solid recovered fuel, corporate upcycling and the innovative BtoB recycling program "Recycled clothingTM".

In 2017, CEPOVETT Group incorporated recycled polyester into several of its customers' clothing collections, including the airline Joon and the Lancel brand. In addition to using recycled polyester, the company innovated this year by combining it with "post-consumer" recycled cotton from the end-of-life garments of one of its customers. In all, nearly 15 tons of textile waste from CEPOVETT Group's activities were reclaimed in 2017.

Focus 2017

2017 Report

CEPOVETT Group has made the recycling and end-of-life of its products a priority in its corporate social responsibility policy, in association with exclusive, leading industrial partners, to invent innovative, tailor-made solutions that are both socio-economic and environmental. Since 2011, the recycling program set up by CEPOVETT Group has used different ways of reclaiming end-of-life professional textiles: sound and heat insulation for the automotive industry or housing, solid recovered fuel or corporate upcycling. In 2016, the "Recycled clothing ™" recycling innovation was a first for the professional textile sector. It made it possible to manufacture a new professional garment using recycled fibers from old workwear - post-consumer. This innovative approach inspired by the circular economy makes it possible to separate and extract the cotton from used garments and then manufacture a new fabric from a "regenerated recycled yarn". All these recycling solutions have the same aim: to give a second life to used workwear. Nearly 50 tonnes of textile waste from CEPOVETT Group's activities were recovered in 2016.

Focus 2016

2016 Report

CEPOVETT Group has made the recycling of end-of-life workwear a priority by implementing innovative recycling solutions. Since 2011, CEPOVETT Group has been offering its customers to take charge of the entire textile recovery process, from collection to recycling. A real success, over 200 tonnes of used clothing have already been recycled. In 2015, CEPOVETT Group developed a socio-economic and environmental textile revalorization program in the form of tailor-made solutions, adapted to the challenges faced by its customers. The possibilities for recycling are numerous, ranging from solidarity-based reuse to textile materials or biomass energy conversion: textile waste is incinerated to produce heat and electricity. With the determination to go even further, CEPOVETT Group is experimenting with the "cradle-to-cradle*" workwear of tomorrow. *from cradle to cradle.