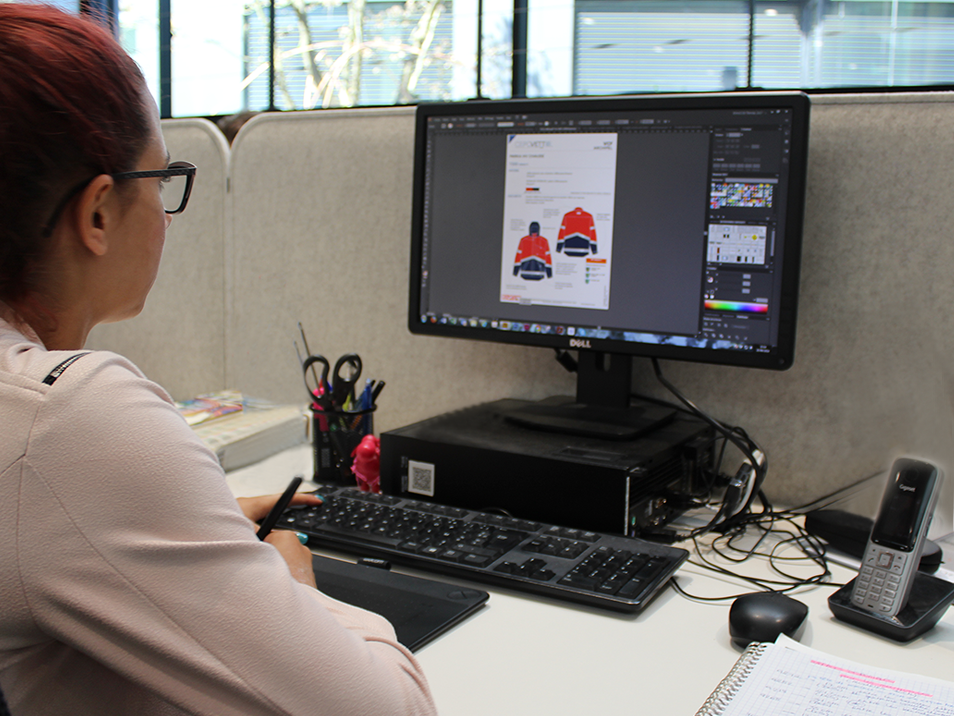

WORKWEAR DESIGN

INTEGRATED PRODUCT DESIGN AND DEVELOPMENT MANAGEMENT

Throughout its history, CEPOVETT Group has cultivated a spirit of proximity without betraying the family values that are part of its DNA. Today, as a European leader, CEPOVETT Group's entrepreneurial spirit is its hallmark, as it designs collections that reflect its customers' image, thanks to integrated management from garment creation through to development and marketing: design office and conception, research and development, development of exclusive fabrics.

Integrated skills

Design and industrialize

We listen to your needs, draw up complete style books, create CAD files, produce prototypes on request, print, screen print, embroider...

Our design office is able to meet the specific needs of each partner, whatever the sector.

Designed entirely in-house, the final product is the result of a close synergy between the R&D department, the prototyping workshop and the company's various departments. We can also collaborate with an independent design office or a major luxury brand, as required.

Each garment collection begins with our technical experts. All the prototypes produced will give life to a new identity collection, which will then be turned into industrializable textile products.

We continue to promote the use of eco-responsible materials, for the greater comfort of users, both for their ecological and recyclable properties.

Ongoing collaboration between designers, pattern makers and industrialization technicians

collections designed per year

textile designers and technicians

industrialized prototypes per year

Garment design - Modeling - Prototyping - Technical files and industrialization - Size grading

A new integrated textile laboratory

Imagining and creating

A synergy of creative and technical resources for your collection

Our mission is to decode and decipher your image. Translate your corporate or brand values into a creative and meaningful clothing collection.

We support your project from start to finish, from creative brainstorming to the deployment of your collection among your employees. Our approach is both creative and industrial, serving your communication challenges through professional apparel.

Trend studies, functions and workstations l Branding (textile DNA, exclusive collections, fashion accessories...) l Digital communication (3D design, e-catalogue, WMS...) l Deployment of the collection among your employees (dress-code, road-show, fashion shows...)

Choosing garment makers and production sites

PARTNER SELECTION CHARTER

All plants have been tested and approved by CEPOVETT Group for many years, and comply with the quality and CSR standards imposed by its customers.

The supplier selection and referencing procedure naturally takes into account the supplier's ability to deliver a finished product in compliance with specifications, but also the supplier's commitment to social aspects.

Our selections are based on a number of essential criteria:

- Security: security of material supply, guaranteed ease of maintenance and long-lasting performance, guaranteed delivery times, technical capacity to control batch quality consistency: material conformity, color over time, resistance.

- Comfort

- Value for money

- Total respect for the environment

- Knowledge of the requirements of each business

- Transparency in contractual relations (factory visits and audits)